Page 9 - PACE Katalógus

P. 9

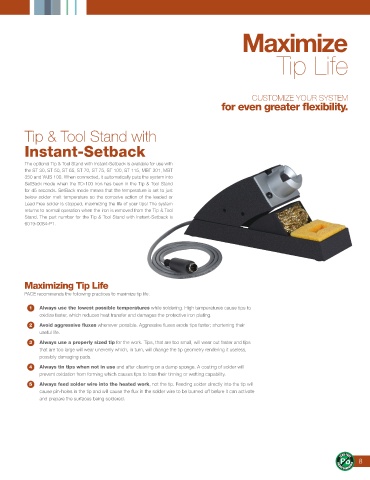

Maximize

Tip Life

CUSTOMIZE YOUR SYSTEM

for even greater flexibility.

Tip & Tool Stand with

Instant-Setback

The optional Tip & Tool Stand with Instant-Setback is available for use with

the ST 30, ST 50, ST 65, ST 70, ST 75, ST 100, ST 115, MBT 301, MBT

350 and WJS 100. When connected, it automatically puts the system into

SetBack mode when the TD-100 Iron has been in the Tip & Tool Stand

for 45 seconds. SetBack mode means that the temperature is set to just

below solder melt temperature so the corrosive action of the leaded or

Lead Free solder is stopped, maximizing the life of your tips! The system

returns to normal operation when the iron is removed from the Tip & Tool

Stand. The part number for the Tip & Tool Stand with Instant-Setback is

6019-0084-P1.

Maximizing Tip Life

PACE recommends the following practices to maximize tip life.

1 Always use the lowest possible temperatures while soldering. High temperatures cause tips to

oxidize faster, which reduces heat transfer and damages the protective iron plating.

2 Avoid aggressive fluxes whenever possible. Aggressive fluxes erode tips faster; shortening their

useful life.

3 Always use a properly sized tip for the work. Tips, that are too small, will wear out faster and tips

that are too large will wear unevenly which, in turn, will change the tip geometry rendering it useless,

possibly damaging pads.

4 Always tin tips when not in use and after cleaning on a damp sponge. A coating of solder will

prevent oxidation from forming which causes tips to lose their tinning or wetting capability.

5 Always feed solder wire into the heated work, not the tip. Feeding solder directly into the tip will

cause pin-holes in the tip and will cause the flux in the solder wire to be burned off before it can activate

and prepare the surfaces being soldered.

8