Page 74 - weller

P. 74

Soldering Stations | BGA / QFP Repair

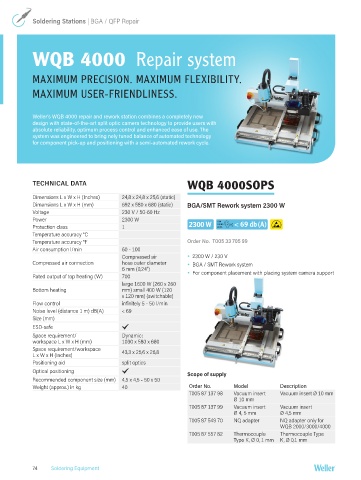

WQB 4000 Repair system

MAXIMUM PRECISION. MAXIMUM FLEXIBILITY.

MAXIMUM USER-FRIENDLINESS.

Weller’s WQB 4000 repair and rework station combines a completely new

design with state-of-the-art split optic camera technology to provide users with

absolute reliability, optimum process control and enhanced ease of use. The

system was engineered to bring nely tuned balance of automated technology

for component pick-up and positioning with a semi-automated rework cycle.

TECHNICAL DATA WQB 4000SOPS

Dimensions L x W x H (Inches) 24,8 x 24,8 x 25,6 (static)

Dimensions L x W x H (mm) 692 x 580 x 680 (static) BGA/SMT Rework system 2300 W

Voltage 230 V / 50-60 Hz

Power 2300 W LOW

Protection class 1 2300 W SOUND < 69 db (A)

LEVEL

Temperature accuracy °C

Temperature accuracy °F Order No. T005 33 705 99

Air consumption l/min 60 - 100

Compressed air 2300 W / 230 V

Compressed air connection hose outer diameter BGA / SMT Rework system

6 mm (0,24")

Rated output of top heating (W) 700 For component placement with placing system camera support

large 1600 W (260 x 260

Bottom heating mm) small 400 W (120

x 120 mm) (switchable)

Flow control infinitely 5 - 50 l/min

Noise level (distance 1 m) dB(A) < 69

Size (mm)

ESD-safe .

Space requirement/ Dynamic:

workspace L x W x H (mm) 1030 x 580 x 680

Space requirement/workspace 43,3 x 25,6 x 26,8

L x W x H (Inches)

Positioning aid split optics

Optical positioning . Scope of supply

Recommended component size (mm) 4,5 x 4,5 - 50 x 50

Weight (approx.) in kg 40 Order No. Model Description

T005 87 137 98 Vacuum insert Vacuum insert Ø 10 mm

Ø 10 mm

T005 87 137 99 Vacuum insert Vacuum insert

Ø 4, 5 mm Ø 4,5 mm

T005 87 549 70 NQ adapter NQ adapter only for

WQB 2000/3000/4000

T005 87 557 82 Thermocouple Thermocouple Type

Type K, Ø 0, 1 mm K, Ø 0,1 mm

74 Soldering Equipment