Page 75 - weller

P. 75

Soldering Stations | BGA / QFP Repair

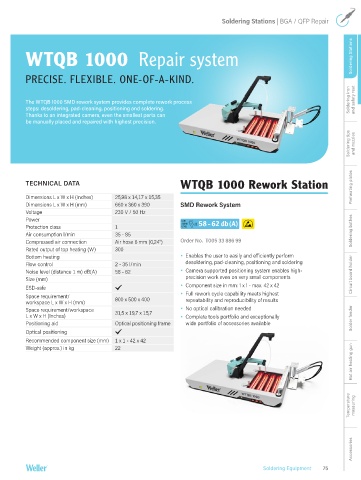

WTQB 1000 Repair system Soldering Stations

PRECISE. FLEXIBLE. ONE-OF-A-KIND.

The WTQB 1000 SMD rework system provides complete rework process Soldering iron and safety rest

steps: desoldering, pad-cleaning, positioning and soldering.

Thanks to an integrated camera, even the smallest parts can

be manually placed and repaired with highest precision.

Soldering tips and nozzles

TECHNICAL DATA WTQB 1000 Rework Station Preheating plates

Dimensions L x W x H (Inches) 25,98 x 14,17 x 15,35

Dimensions L x W x H (mm) 660 x 360 x 390 SMD Rework System

Voltage 230 V / 50 Hz

Power LOW

Protection class 1 SOUND 58 - 62 db (A)

LEVEL

Air consumption l/min 35 - 85 Soldering bathes

Compressed air connection Air hose 6 mm (0,24“) Order No. T005 33 886 99

Rated output of top heating (W) 300

Bottom heating Enables the user to easily and efficiently perform

Flow control 2 - 35 l/min desoldering, pad-cleaning, positioning and soldering

Noise level (distance 1 m) dB(A) 58 - 62 Camera supported positioning system enables high-

Size (mm) precision work even on very small components Circuit board holder

ESD-safe . Component size in mm: 1 x 1 - max. 42 x 42

Space requirement/ 800 x 500 x 400 Full rework cycle capability meets highest

workspace L x W x H (mm) repeatability and reproducibility of results

Space requirement/workspace 31,5 x 19,7 x 15,7 No optical calibration needed

L x W x H (Inches) Complete tools portfolio and exceptionally Solder feeder

Positioning aid Optical positioning frame wide portfolio of accessories available

Optical positioning .

Recommended component size (mm) 1 x 1 - 42 x 42

Hot air heating gun

Weight (approx.) in kg 22

Temperature measuring

Accessories

Soldering Equipment 75