Page 37 - ERSA

P. 37

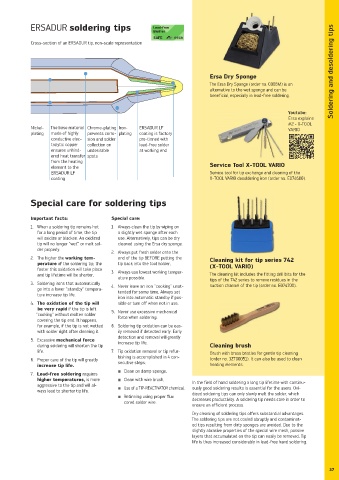

ERSADUR soldering tips

Soldering and desoldering tips

Cross-section of an ERSADUR tip, non-scale representation

Ersa Dry Sponge

The Ersa Dry Sponge (order no. 0008M) is an

alternative to the wet sponge and can be

beneficial, especially in lead-free soldering.

Youtube:

Ersa explains

#2 - X-TOOL

Nickel- The base material Chrome-plating Iron- ERSADUR LF VARIO

plating made of highly prevents corro- plating coating is factory

conductive elec- sion and solder pre-tinned with

trolytic copper collection on lead-free solder

ensures unhind- undesirable at working end

ered heat transfer spots

from the heating Service Tool X-TOOL VARIO

element to the

ERSADUR LF Service tool for tip exchange and cleaning of the

coating X-TOOL VARIO desoldering iron (order no. E074600).

Special care for soldering tips

Important facts: Special care:

1. When a soldering tip remains hot 1. Always clean the tip by wiping on

for a long period of time, the tip a slightly wet sponge after each

will oxidize or blacken. An oxidized use. Alternatively, tips can be dry

tip will no longer “wet“ or melt sol- cleaned using the Ersa dry sponge.

der properly.

2. Always put fresh solder onto the

2. The higher the working tem- end of the tip BEFORE putting the Cleaning kit for tip series 742

perature of the soldering tip, the tip back into the tool holder. (X-TOOL VARIO)

faster this oxidation will take place 3. Always use lowest working temper-

and tip lifetime will be shorter. The cleaning kit includes the fitting drill bits for the

ature possible. tips of the 742 series to remove residues in the

3. Soldering irons that automatically 4. Never leave an iron “cooking” unat- suction channel of the tip (order no. E074700).

go into a lower “standby” tempera-

ture increase tip life. tended for some time. Always set

iron into automatic standby if pos-

4. The oxidation of the tip will sible or turn off when not in use.

be very rapid if the tip is left

“cooking” without molten solder 5. Never use excessive mechanical

force when soldering.

covering the tip end. It happens,

for example, if the tip is not wetted 6. Soldering tip oxidation can be eas-

with solder right after cleaning it. ily removed if detected early. Early

detection and removal will greatly

5. Excessive mechanical force increase tip life.

during soldering will shorten the tip Cleaning brush

life. 7. Tip oxidation removal or tip refur- Brush with brass bristles for gentle tip cleaning

bishing is accomplished in 4 con-

6. Proper care of the tip will greatly secutive steps: (order no. 3ZT00051). It can also be used to clean

increase tip life. heating elements.

Clean on damp sponge,

7. Lead-free soldering requires

higher temperatures, is more Clean with wire brush, In the field of hand soldering a long tip lifetime with continu-

aggressive to the tip and will al- Use of a TIP-REACTIVATOR chemical, ously good soldering results is essential for the users. Oxi-

ways lead to shorter tip life. dized soldering tips can only slowly melt the solder, which

Retinning using proper flux decreases productivity. A soldering tip needs care in order to

cored solder wire.

ensure an efficient process.

Dry cleaning of soldering tips offers substantial advantages.

The soldering tips are not cooled abruptly and contaminat-

ed tips resulting from dirty sponges are avoided. Due to the

slightly abrasive properties of the special wire mesh, passive

layers that accumulated on the tip can easily be removed. Tip

life is thus increased considerably in lead-free hand soldering.

37