Page 34 - ERSA

P. 34

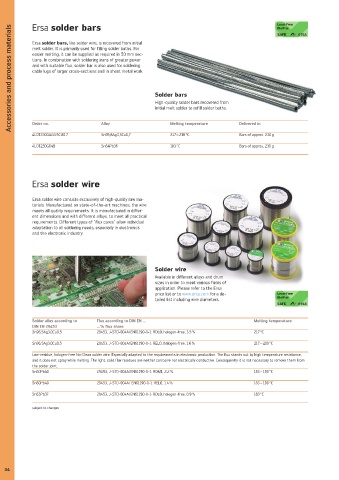

Ersa solder bars

Accessories and process materials

Ersa solder bars, like solder wire, is recovered from initial

melt solder. It is primarily used for filling solder baths. For

easier melting, it can be supplied as required in 50 mm sec-

tions. In combination with soldering irons of greater power

and with suitable flux, solder bar is also used for soldering

cable lugs of larger cross-sections and in sheet metal work.

Solder bars

High-quality solder bars recovered from

initial melt solder to refill solder baths.

Order no. Alloy Melting temperature Delivered in

4LOT230GAG3.5CU0.7 Sn95,8Ag3,5Cu0,7 217 – 218 °C Bars of approx. 230 g

4LOT230G64B Sn64Pb36 183 °C Bars of approx. 230 g

Ersa solder wire

Ersa solder wire consists exclusively of high-quality raw ma-

terials. Manufactured on state-of-the-art machines, the wire

meets all quality requirements. It is manufactured in differ-

ent dimensions and with different alloys, to meet all practical

requirements. Different types of “flux cores” allow individual

adaptation to all soldering needs, especially in electronics

and the electronic industry.

Solder wire

Available in different alloys and drum

sizes in order to meet various fields of

application. Please refer to the Ersa

price list or to www.ersa.com for a de-

tailed list including wire diameters.

Solder alloy according to Flux according to DIN EN ... Melting temperature

DIN EN 29453 ... % flux share

Sn96,5Ag3,0Cu0,5 29453, J-STD-004A/EN61190-1-1: ROL0, halogen-free, 3.5 % 217 °C

Sn96,5Ag3,0Cu0,5 29453, J-STD-004A/EN61190-1-1: RELO, halogen-free, 1.6 % 217 – 219 °C

Low-residue, halogen-free No-Clean solder wire. Especially adapted to the requirements in electronic production. The flux stands out by high temperature resistance,

and it does not spray while melting. The light, solid flux residues are neither corrosive nor electrically conductive. Consequently it is not necessary to remove them from

the solder joint.

Sn60Pb40 29453, J-STD-004A/EN61190-1-1: ROM1, 2.2 % 183 – 190 °C

Sn60Pb40 29453, J-STD-004A/ EN61190-1-1: REL0, 1.4 % 183 – 190 °C

Sn63Pb37 29453, J-STD-004A/EN61190-1-1: ROL0, halogen-free, 0.9 % 183 °C

subject to changes

34