Page 266 - WERA katalógus

P. 266

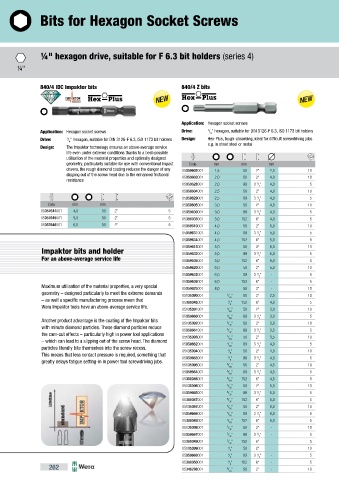

Bits for Hexagon Socket Screws

¼" hexagon drive, suitable for F 6.3 bit holders (series 4)

¼"

840/4 IDC Impaktor bits 840/4 Z bits

Application: Hexagon socket screws

Application: Hexagon socket screws Drive: 1 / " hexagon, suitable for DIN 3126-F 6.3, ISO 1173 bit holders

4

Drive: 1 / " hexagon, suitable for DIN 3126-F 6.3, ISO 1173 bit holders Design: Hex-Plus, tough-absorbing, ideal for diffi cult screwdriving jobs

4

Design: The Impaktor technology ensures an above-average service e.g. in sheet steel or metal

life even under extreme conditions thanks to a best-possible

utilisation of the material properties and optimally designed

geometry, particularly suitable for use with conventional impact Code mm mm mm

drivers, the rough diamond coating reduces the danger of any 05059602001 1,5 50 2" 2,0 10

slipping out of the screw head due to the enhanced frictional 05059603001 2,0 50 2" 4,0 10

resistance

1

05059628001 2,0 89 3 / " 4,0 5

2

05059604001 2,5 50 2" 4,0 10

05059629001 2,5 89 3 / " 4,0 5

1

2

Code mm mm 05059605001 3,0 50 2" 4,0 10

05057644001 4,0 50 2" 5 05059630001 3,0 89 3 / " 4,0 5

1

2

05057645001 5,0 50 2" 5 05380033001 3,0 152 6" 4,0 5

05057646001 6,0 50 2" 5 05059610001 4,0 50 2" 5,0 10

05059631001 4,0 89 3 / " 5,0 5

1

2

05059634001 4,0 152 6" 5,0 5

2"

Impaktor bits and holder 05059615001 5,0 50 3 / " 6,0 10

1

5,0

6,0

05059632001

5

89

For an above-average service life 05059635001 5,0 152 6" 2 6,0 5

05059620001 6,0 50 2" 5,0 10

05059633001 6,0 89 3 / " - 5

1

2

05059636001 6,0 152 6" - 5

Maximum utilisation of the material properties, a very special 05059625001 8,0 50 2" - 10

geometry – designed particularly to meet the extreme demands 05135090001 1 / " 50 2" 2,5 10

16

– as well a specifi c manufacturing process mean that 05380045001 1 / " 152 6" 4,0 5

Wera Impaktor tools have an above-average service life. 8

05135091001 5 / " 50 2" 3,0 10

64

05059660001 5 / " 89 3 / " 3,0 5

1

64

2

Another product advantage is the coating of the Impaktor bits 05135092001 3 / " 50 2" 3,0 10

32

with minute diamond particles. These diamond particles reduce 05059661001 3 / " 89 3 / " 3,5 5

1

32

the cam-out eff ects – particularly high in power tool applications 05135093001 7 / " 50 2" 2 3,5 10

64

– which can lead to a slipping out of the screw head. The diamond 05059662001 7 / " 89 3 / " 4,0 5

1

64

particles literally bite themselves into the screw recess. 05135094001 1 / " 50 2" 2 4,0 10

8

This means that less contact pressure is required, something that 05059663001 1 / " 89 3 / " 4,0 5

1

greatly delays fatigue setting-in in power tool screwdriving jobs. 8 2

05135095001 9 / " 50 2" 4,5 10

64

05059664001 9 / " 89 3 / " 4,5 5

1

64 2

05380046001 9 / " 152 6" 4,5 5

64

05135096001 5 / " 50 2" 5,0 10

32

05059665001 5 / " 89 3 / " 5,0 5

1

32 2

05380047001 5 / " 152 6" 5,0 5

32

05135097001 3 / " 50 2" 6,0 10

16

1

05059666001 3 / " 89 3 / " 6,0 5

2

16

05380048001 3 / " 152 6" 6,0 5

16

05135098001 7 / " 50 2" - 10

32

1

05059667001 7 / " 89 3 / " - 5

32 2

05380049001 7 / " 152 6" - 5

32

05135099001 1 / " 50 2" - 10

4

05059668001 1 / " 89 3 / " - 5

1

4

2

05380050001 1 / " 152 6" - 5

4

262 05346288001 5 / " 50 2" - 10

16