Page 18 - VERMASON ESD katalógus

P. 18

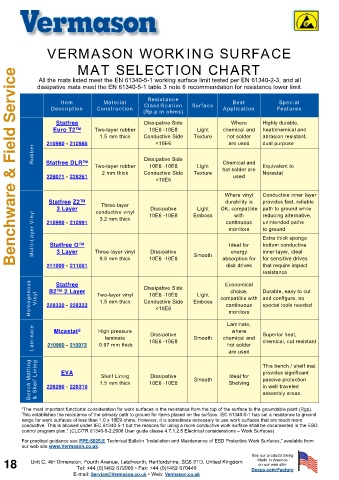

VERMASON WORKING SURFACE

MAT SELECTION CHART

Benchware & Field Service

All the mats listed meet the EN 61340-5-1 working surface limit tested per EN 61340-2-3, and all

dissipative mats meet the EN 61340-5-1 table 3 note 6 recommendation for resistance lower limit.

Resistance

Item Material Classification Surface Best Special

Description Construction (Rp-p in ohms) Application Features

Statfree Dissipative Side Where Highly durable,

Euro T2™ Two-layer rubber 10E6 -10E8 Light chemical and heat/chemical and

1.5 mm thick Conductive Side Texture hot solder abrasion resistant,

210980 - 210985 <10E6 are used dual purpose

Rubber Dissipative Side

Statfree DLR™

Two-layer rubber 10E6 -10E8 Light Chemical and Equivalent to

hot solder are

2 mm thick Conductive Side Texture Norastat

228071 - 228261 used

<10E6

Where vinyl Conductive inner layer

Statfree Z2™ Three-layer durability is provides fast, reliable

3 Layer conductive vinyl 10E6 -10E8 Emboss OK, compatible path to ground while

Light

Dissipative

Multi-Layer Vinyl 210990 - 210991 continuous unintended paths

with

reducing alternative,

3.2 mm thick

to ground

monitors

Extra thick sponge

bottom conductive

Statfree O™

Ideal for

Three-layer vinyl

Dissipative

energy

3 Layer

9.5 mm thick 10E6 -10E8 Smooth absorption for inner layer, ideal

for sensitive drives

211000 - 211001 disk drives that require impact

resistance

Homogenous Vinyl 228330 - 228333 Two-layer vinyl Dissipative Side Emboss compatible with and configure, no

Statfree

Economical

B2™ 2 Layer

Durable, easy to cut

choice,

10E6 -10E8

Light

1.5 mm thick

Conductive Side

special tools needed

continuous

<10E6

monitors

Laminate,

Laminate 210960 - 210973 0.97 mm thick 10E6 -10E8 Smooth chemical and Superior heat,

Micastat

where

High pressure

®

Dissipative

laminate

chemical, cut resistant

hot solder

are used

Bench Matting & Shelf Lining 228290 - 228310 1.5 mm thick 10E6 -10E8 Smooth Shelving This bench / shelf mat

EVA

provides significant

Dissipative

Shelf Lining

Ideal for

passive protection

in well-traveled

assembly areas.

“The most important functional consideration for work surfaces is the resistance from the top of the surface to the groundable point (Rgp).

This establishes the resistance of the primary path to ground for items placed on the surface. IEC 61340-5-1 has set a resistance to ground

range for work surfaces of less than 1,0 x 10E9 ohms. However, it is sometimes necessary to use work surfaces that are much more

conductive. This is allowed under IEC 61340-5-1 but the reasons for using a more conductive work surface shall be documented in the ESD

control program plan.” (CLC/TR 61340-5-2:2008 User guide clause 4.7.1.2.5 Electrical considerations – Work Surfaces)

For practical guidance see PPE-5025.E Technical Bulletin “Installation and Maintenance of ESD Protective Work Surfaces,” available from

our web site www.Vermason.co.uk.

See our products being

18 Unit C, 4th Dimension, Fourth Avenue, Letchworth, Hertfordshire, SG6 2TD, United Kingdom Made in America

on our web site:

Tel: +44 (0)1462 672005 • Fax: +44 (0)1462 670440

E-mail: Service@Vermason.co.uk • Web: Vermason.co.uk Desco.com/Factory