Page 6 - Treston workspaces

P. 6

Investing in an EPA is important

There are two types of ESD damage in industrial and bear eyes and the product may pass all tests and function

technical environments. Firstly, a fatal defect that is usually normally for some time. However, latent damage affects the

easily detected during assembly or handling, or at least performance and durability of the product and and often

through careful testing. Such products are usually not results in poor product quality.

delivered to customers. Secondly, another type of ESD

damage is latent damage. This is difficult to detect with

Static charge management of a working area:

• ESD-protected workstations. Attention paid to ESD safe storing, moving and packing.

• Personnel protected with shoes, wrist straps and other needed accessories

• Staff training, work instructions and quality control

• Cleanliness of ESD-protected equipment. Dust and dirt insulate.

• Commitment to continuous improvement in static electricity management

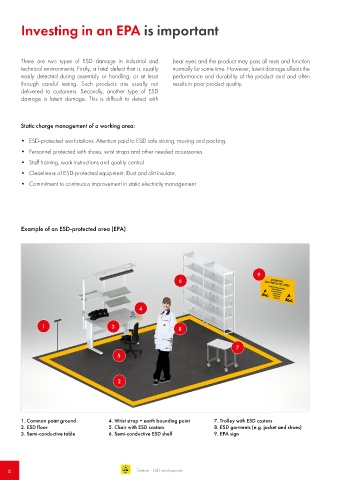

Example of an ESD-protected area (EPA)

9

6

4

1 3 8

7

5

2

1. Common point ground 4. Wrist strap + earth bounding point 7. Trolley with ESD castors

2. ESD floor 5. Chair with ESD castors 8. ESD garments (e.g. jacket and shoes)

3. Semi-conductive table 6. Semi-conductive ESD shelf 9. EPA sign

6 Treston - ESD workspaces