Page 15 - ABEBA PROTEKTOR

P. 15

LINE CONSTRUCT CONSTRUCT CONSTRUCT CONSTRUCT CONSTRUCT CONSTRUCT CONSTRUCT CONSTRUCT CONSTRUCT CONSTRUCT

article number 5005850 5005851 5010850 5010851 5025850 5025851 5010940 5010906 5010956 5010864

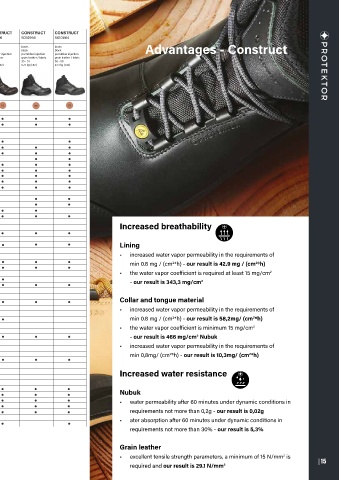

footwear type shoes boots shoes boots shoes boots boots boots boots boots Advantages - Construct

color beige beige black black gray gray black black black black

assembly system / type of sole pu/rubber injection pu/rubber injection pu/rubber injection pu/rubber injection pu/rubber injection pu/rubber injection pu/rubber injection pu/rubber injection pu/rubber injection pu/rubber injection

upper material nubuck nubuck grain leather grain leather nubuck nubuck grain leather grain leather grain leather / fabric grain leather / fabric

sizes 38 - 48 38 - 48 35 - 51 35 - 51 38 - 48 36 - 48 36 - 50 36 - 50 35 - 51 36 - 50

weight of a half pair 0,64 kg (r.42) 0,70 kg (r.42) 0,67 kg (r.42) 0,72 kg (r.42) 0,64 kg (r.42) 0,70 kg (r.42) 0,75 kg (r.42) 0,85 kg (r.42) 0,73 kg (r.42) 0,73 kg (r.42)

PROTECTION CATEGORY

HI3

P

SRC

SRB

SRA

ESD

PROPERTIES A E

FO

HI

CI

HRO

WR

WRU

SLIP RESISTANCE

INCREASED BREATHABILITY

WATER RESISTANCE

DURABILITY OF THE UPPER

TOE CAP COMPOSITE Increased breathability

STEEL

ALUMINIUM

HEAT-RESISTANT SOLE

NON-FLAMMABLE SOLE

METAL FREE Lining

EASY-CLEAN UPPER

ANTIBACTERIAL LINING • increased water vapor permeability in the requirements of

ADDITIONAL FEATURES TOE CAP PROTECTION • the water vapor coefficient is required at least 15 mg/cm

MEMBRANE LINING

min 0.8 mg / (cm *h) - our result is 42.9 mg / (cm *h)

2

2

2

HEAT RESISTANT LEATHER

REFLECTIVE ELEMENTS

- our result is 343,3 mg/cm

2

BELLOWS TONGUE

QUICK DONNING SYSTEM

QUICK SHOE REMOVAL SYSTEM Collar and tongue material

LADDER SOLE

NO LINING • increased water vapor permeability in the requirements of

ANKLE PROTECTION

2

2

INSULATED min 0.8 mg / (cm *h) - our result is 58,2mg/ (cm *h)

ANTIBACTERIAL • the water vapor coefficient is minimum 15 mg/cm

2

ORTHOPEDIC

INSOLE REPLACEABLE - our result is 466 mg/cm Nubuk

2

INTEGRATED

MASSAGE • increased water vapor permeability in the requirements of

2

2

AUTOCLAVABLE min 0,8mg/ (cm *h) - our result is 10,3mg/ (cm *h)

DISINFECTION

OTHER WASHABLE 30°C Increased water resistance

WASHABLE 60°C

HACCP

ATEX

PRT FLEX Nubuk

SHOCK ABSORBER

TECHNOLOGIES ANA-TECH • water permeability after 60 minutes under dynamic conditions in

SELF CLEAN

requirements not more than 0,2g - our result is 0,02g

PRO-TENDON

UV PROTECTION

COLD PROTECTION • ater absorption after 60 minutes under dynamic conditions in

requirements not more than 30% - our result is 5,3%

Grain leather

• excellent tensile strength parameters, a minimum of 15 N/mm is

2

14 | | 15

required and our result is 29.1 N/mm 2